In the construction industry, the commonly used wall materials in China can be divided into two categories, namely

solid clay bricks and new wall materials.

Solid clay brick (commonly known as red brick), made of clay as the main material by sintering process, is the main

wall material in China for a long time because of its simple process equipment and a long history of use.

Non-clay bricks, building blocks and other new wall materials made of cement, sand and stone and fly ash, coal gangue,

slag and other industrial wastes or construction waste as the main materials are stirred, vibrated, pressed and other industries.

Similar new wall materials have been gradually promoted and popularized in China in recent ten years, among which concrete

blocks are the most commonly used.

According to the different forming process, the brick machine equipment can be divided into two categories: brick

press machine and block forming machine.

The brick machine that shapes the brick body (block) through high pressure extrusion is collectively referred to as the

brick press;The brick machine that shapes the brick body (block) through vibration extrusion is collectively referred to

as the block forming machine. The block forming machine has a high degree of automation, many types of blocks (bricks)

that can be produced, and large output, which is in a leading position in the brick machine equipment and is the most widely used.

A fully automatic block forming machine is mainly composed of belt conveyor, vibration forming machine (main machine),

plate feeding machine, brick out machine, palletizer, control cabinet, hydraulic pump station, etc. The vibration forming

device is the core part of the block forming machine, and its performance directly determines the quality of the machine

itself and the forming block.

According to the position of the vibration source, the block forming machine can be divided into: table vibration machine

and mold vibration machine.

The model whose vibration source acts directly on the shaking table is called the shaking machine, and the model begins

with "QT". The model whose vibration source is installed on the mold box is called the mold vibration machine, and the

model begins with "QM".

The motor frequently starts directly (3 to 4 minutes per minute), the starting current is large (5 to 7 times the rated

current), the motor temperature rises (70℃),Bearing grease is easy to melt and cause motor damage;

The contactor operates frequently, the passing current is large, and the contact is easy to age;

When the power supply is low, the motor is difficult to start with load;

The running time of the motor each start is 2~4s, the average power factor is low, and the line loss is serious;

When the motor starts directly, the mechanical impact is large, and the requirements for the mechanical parts are high;

Electrical energy from the grid passes through the motor—— Oil pump ——Hydraulic valve tube——After the

transmission of hydraulic motor, it is finally converted into mechanical energy to drive the vibrator, and the process

of energy conversion and transmission is too much, and the efficiency is not high.

The hydraulic system has high cost, large maintenance workload and many wearing parts;

Compared with the motor drive, the hydraulic system has a slow starting pressure and low vibration acceleration;

When the vibrator does not move, the motor and the oil pump have been idling, wasting electric energy;

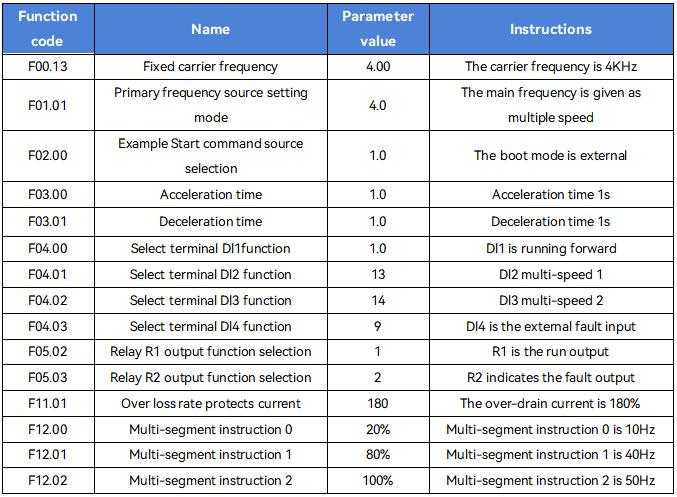

The production data was compared before and after using the FR500A series inverter:

It can be clearly seen from the above data that compared with the motor or hydraulic motor direct drive, the use of

frequency conversion technology in the vibration system has unparalleled advantages:

It can easily realize the frequency modulation of vibration system and meet the production process requirements;

Rapid acceleration and deceleration, save molding time, increase production capacity; Small starting current, less impact

on the power grid; Smooth motor start, small mechanical impact; Low temperature rise of the motor is conducive to

long-term stable operation of the motor; High energy transfer efficiency, saving electric energy; Masonry molding

density is good, the surface is smooth and beautiful; Inverter unique AVR function, even in the case of low grid voltage,

still can output enough voltage to drive the motor work.

Adopt one tow two control; Speed instruction multi-speed control; Adopt alarm system; Inverter adopts V/F control mode;

Acceleration and deceleration time; Energy consumption braking (external braking resistance); The starting current is large,

and the function of over-loss speed is adopted.